Each code is associated with a specific problem, so users will know exactly what is wrong without having to guess.

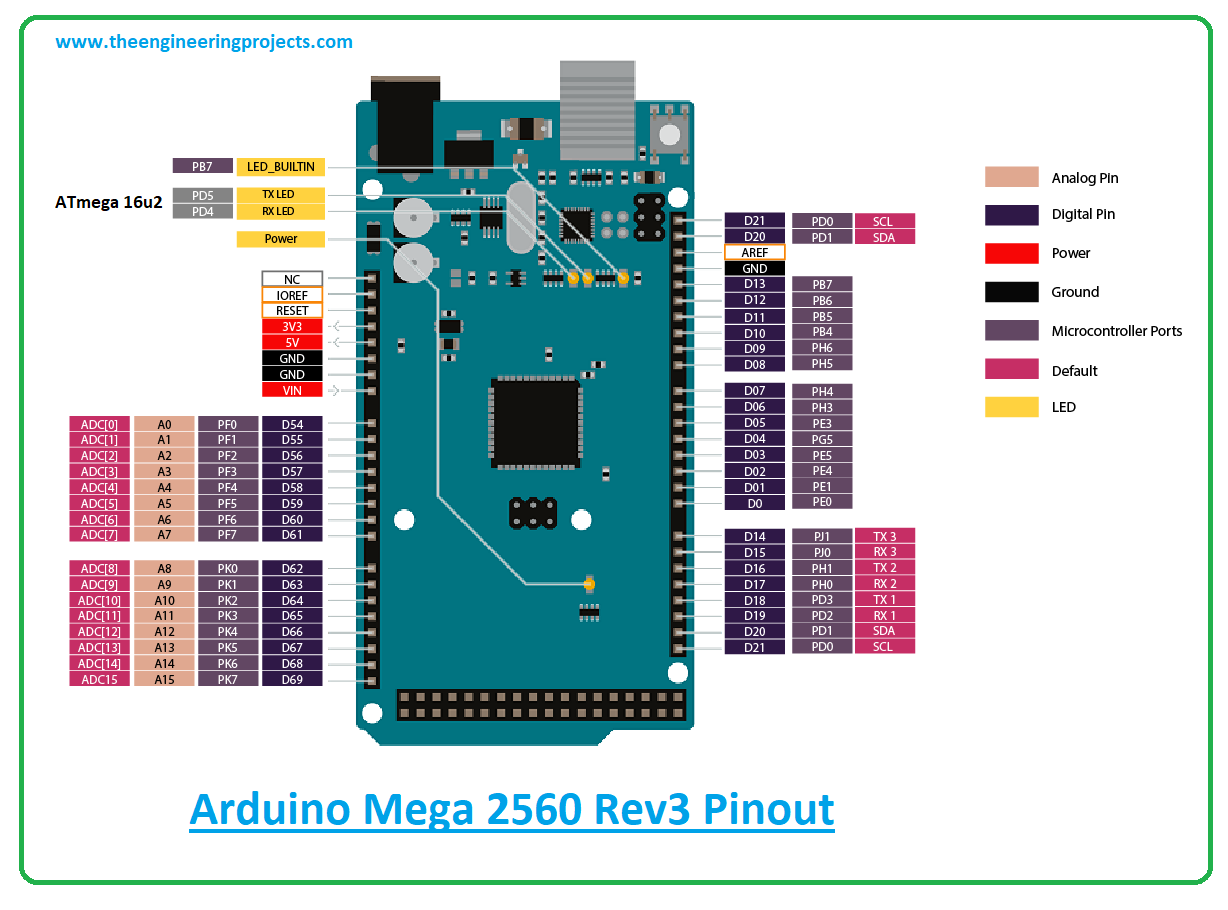

#2560 pinout update

NOTE: GUIs need to specifically update their code to be compatible with v1.1 and later. Based on direct feedback from multiple GUI developers and bench performance testing.

Significant Interface Improvements: Tweaked to increase overall performance, include lots more real-time data, and to simplify maintaining and writing GUIs. Nice to have when you are leaving your machine unattended and want to power down everything automatically. This will disable everything, including the stepper drivers. Sleep Mode : Grbl may now be put to "sleep" via a $SLP command. Dynamic Laser Power Scaling with Speed : If your machine has low accelerations, Grbl will automagically scale the laser power based on how fast Grbl is traveling, so you won't have burnt corners when your CNC has to make a turn! Enabled by the M4 spindle CCW command when laser mode is enabled!.Switch between "laser" mode and "normal" mode via a $ setting. Spindle speed overrides also work with laser mode so you can tweak the laser power, if you need to during the job. When "laser" mode is disabled, Grbl will instead come to a stop to ensure a spindle comes up to speed properly. Laser Mode : The new "laser" mode will cause Grbl to move continuously through consecutive G1, G2, and G3 commands with spindle speed changes. Documentation is included on how this works and how it can be used to control your machine via a joystick or rotary dial with a low-latency, satisfying response. Jogging Mode : The new jogging commands are independent of the g-code parser, so that the parser state doesn't get altered and cause a potential crash if not restored properly. Grbl executes overrides in realtime and within tens of milliseconds. Most hobby CNC's try to mimic this behavior, but usually have large amounts of lag. This awesome new feature is common only on industrial machines, often used to optimize speeds and feeds while a job is running. Real-time Overrides : Alters the machine running state immediately with feed, rapid, spindle speed, spindle stop, and coolant toggle controls. This is due to the addition of two new spindle speed '$' settings. IMPORTANT: Your EEPROM will be wiped and restored with new settings. Official Supporters of the Grbl CNC Project (USA) aka on the wonderful Grbl v0.6 (2011) firmware written by Simen Svale Skogsrud (Norway). Lead Developer: Sungeun "Sonny" Jeon, Ph.D. Licensing: Grbl is free software, released under the GPLv3 license.įor more information and help, check out our Wiki pages! If you find that the information is out-dated, please to help us keep it updated by editing it or notifying our community! Thanks! That means the controller will look up to 24 motions into the future and plan its velocities ahead to deliver smooth acceleration and jerk-free cornering.

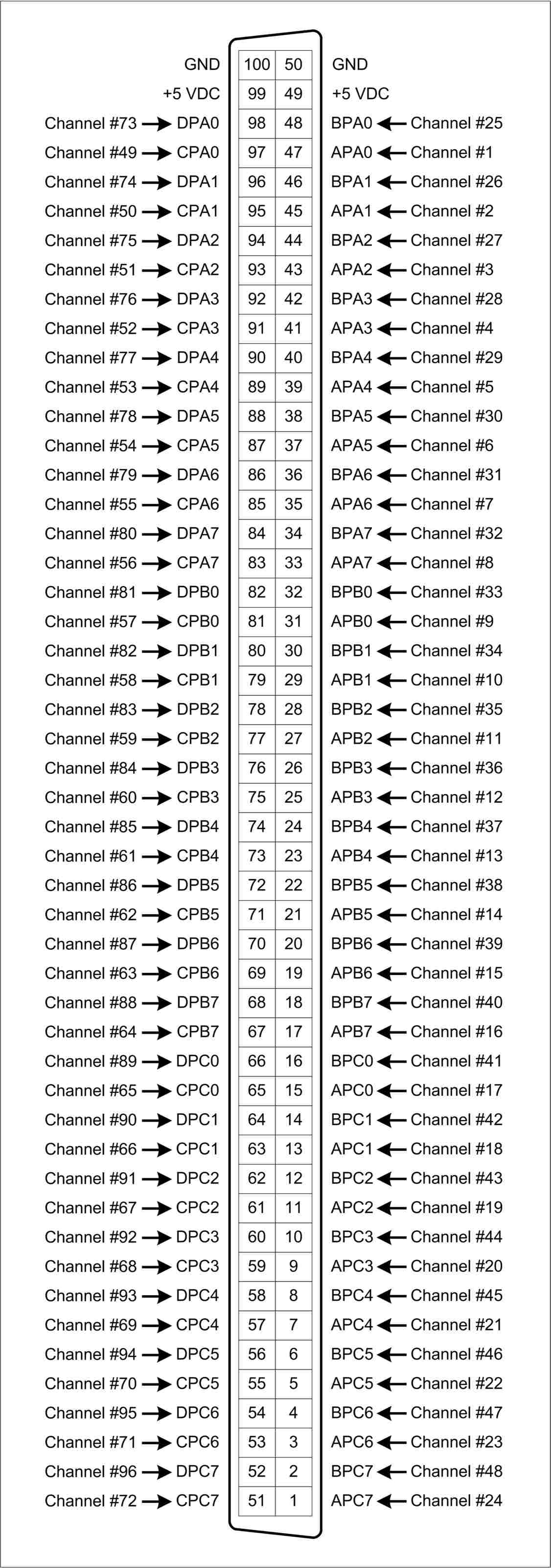

#2560 pinout full

Grbl includes full acceleration management with look ahead. Macro functions, variables, and most canned cycles are not supported, but we think GUIs can do a much better job at translating them into straight g-code anyhow. Arcs, circles and helical motion are fully supported, as well as, all other primary g-code commands. It accepts standards-compliant g-code and has been tested with the output of several CAM tools with no problems. It is able to maintain up to 30kHz of stable, jitter free control pulses. The controller is written in highly optimized C utilizing every clever feature of the AVR-chips to achieve precise timing and asynchronous operation. This version of Grbl runs on an Arduino Mega2560 only. Grbl is a no-compromise, high performance, low cost alternative to parallel-port-based motion control for CNC milling.

#2560 pinout download

Click the Release tab to download pre-compiled.

0 kommentar(er)

0 kommentar(er)